Productivity can be improved by using qIPM to control servo motors because they settle faster so more moves per hour can be achieved.

Also, there is very little jerk which improves the smooth running of the device and, as the servo moves to where it is required with much greater accuracy, there is virtually no wasted energy in correcting over runs which is a substantial saving.

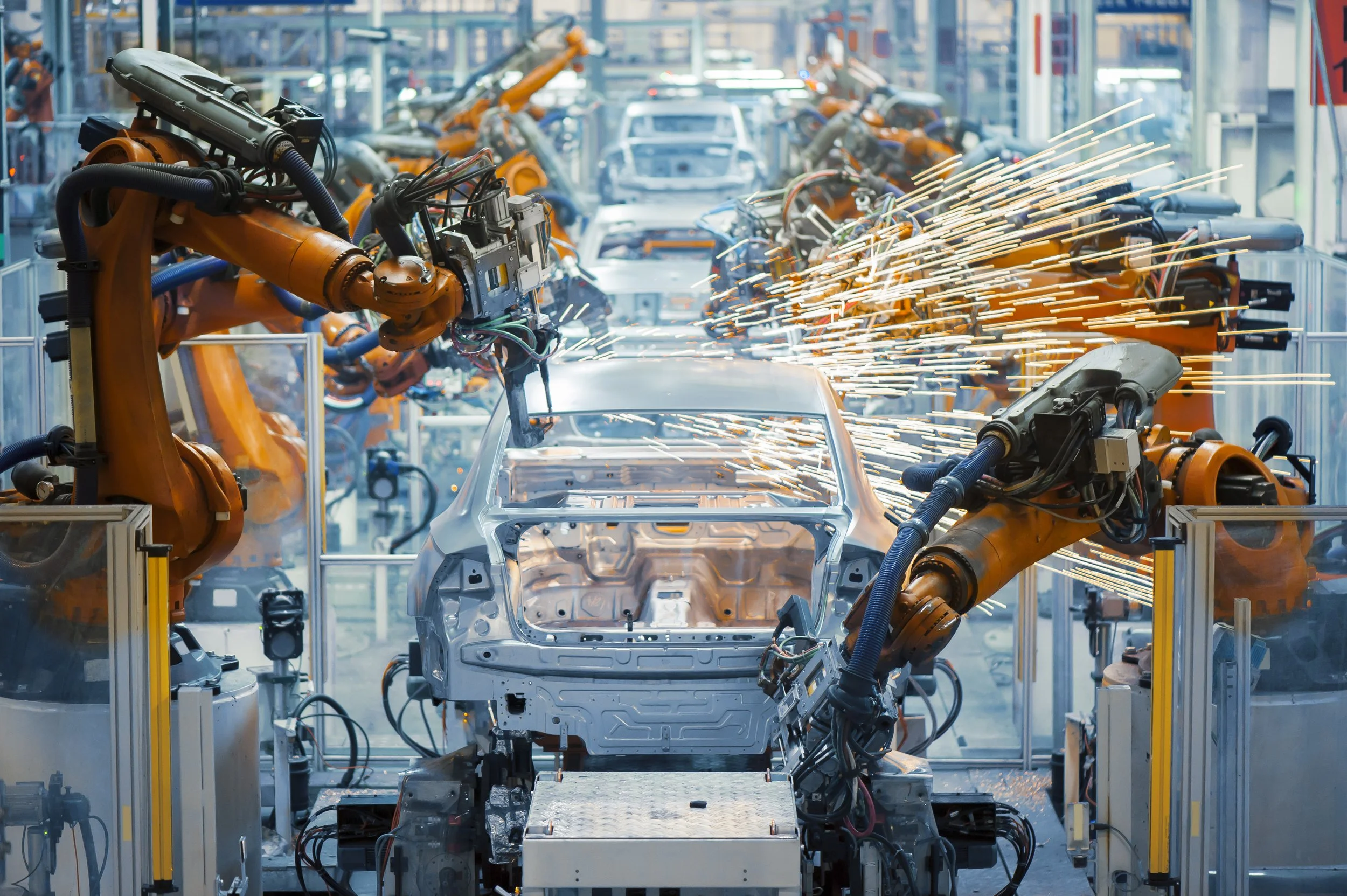

Plus, as explained under high power, integrated motors, removing trailing cables is a major safety improvement from a trip hazard perspective. These cables can also act as antenna picking up ElectroMagnetic Interference (EMI) from high-power welding equipment which can cause errors. Without the need for cables, faraday cages can be used to shield the equipment from other sources of EMI.

Another big problem source of EMI is from welding equipment and we have a solution for this too. Our technology enables high frequency, high power GaN transistors to be used to deliver the huge current required at the welding tip with a very short travel distance of 0.2m rather 5m so there is very little EMI generated and very little power loss.

Application benefits

Sinewave drive and post filter high bandwidth phase current sense

PSD, FFT, discrete time domain analysis in the qControl FPGA/ASIC enables:

• Torque cogging correction – precise velocity control (less scrap due to tolerance errors)

• Machining vibration active correction (better surface finishes, better accuracy of machined surfaces

• Analysis of tool cutting efficiency from vibration analysis

High efficiency and regenerative drive

Save energy and cost through ultra-high frequency switching, reduced cooling requirements and sinewave drive reducing eddy currents, noise and vibrations.

High power density and high efficiency

Integrate the drive and motor in a single package, this provides:

• Only power and control cabling to integrated drive – much simpler cable management

• Lower cost (no long screened cables)

• No EMI issues with encoders

• Fast response as no long cables/inductance – so the machine tool can more accurately follow the toolpath with lower errors

Other application areas

High power integrated motors

Not only does QPT technology cut the power requirements of electrical motors, it also solves a major industry problem of the size of VFD with a VFD design that is around 20 times smaller than today’s VFDs.

Heating, ventilation and air-conditioning (HVAC)

Heating, Ventilation and Air Conditioning (HVAC), uses a huge number of electric motors that are being driven with sub-optimal efficiency.

Electric Vehicles

Electric Vehicles or EV are an ideal market for our technology especially as it enables energy re-capture via regenerative breaking.

Collaborative Robots

Our MicroVFD solution enables greater control and efficiency with lower system complexity and cost, providing significant benefits in the fast-growing cobot market.