The worlds fastest, most accurate, highest resolution, low jitter Isolated GaN Transistor Gate Drive.

The challenge of switching the GaN transistors very fast at around 1-2ns, is that the dv/dt is around 550V/ns or 550kV/us. This rate of change of voltage is too great for any existing isolated gate drives which top out at about 200V/ns and hence cannot drive GaN transistors as fast as they are able to switch, so that, using these current driver ICs, you can't get to the ultimate efficiency that GaN promises.

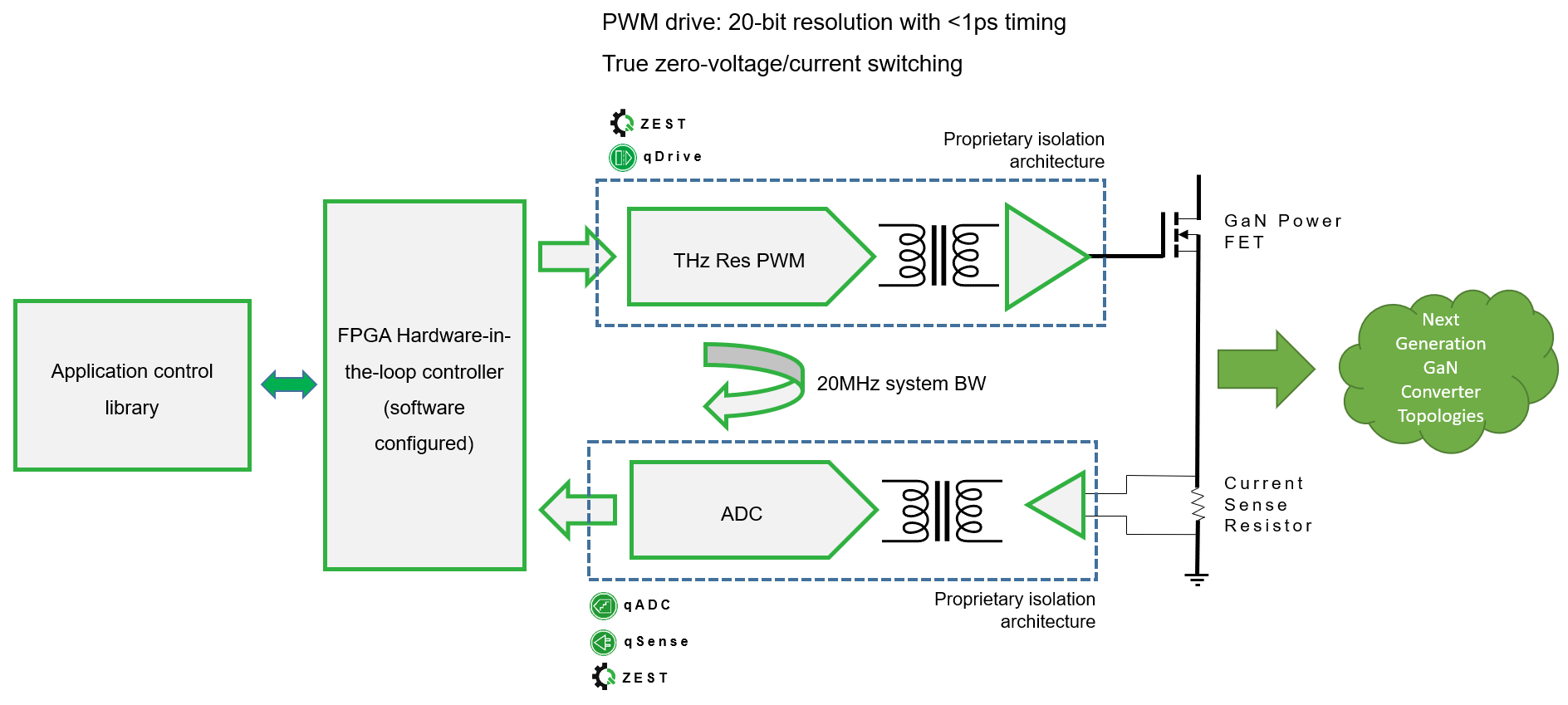

The patented qDrive circuit directly drives the GaN transistors at their maximum frequency of up to 20 MHz with very high timing precision. This is QPT’s core technology that enables GaN to be accurately driven at these frequencies for the first time to unlock their potential.

All currently available isolation and level shifting technologies have around a hundred times too much jitter to work in our next generation converter circuits, so we developed innovative isolation and drive circuitry that made this possible. Our isolation circuitry is based on our patented ZEST™ transformer IP and the level shifting/timing precision comes from proprietary techniques which draw upon our many years of experience in RF and radar systems. These technologies are combined with a revolutionary digital modulation scheme that works in unison with our synchronous, digital loop control systems.

The result is the world’s fastest, most accurate, highest resolution, low jitter, isolated GaN Transistor Gate Drive that unleashes the full potential of GaN power transistors.

qDrive technical specifications

Available under NDA. Please contact us for further details.

Also worth noting is that the propagation delay of our driver is about 3ns. All existing systems are 20ns or more. This is a major problem as they will drift by maybe 5ns or more over time, process, voltage and temperature variations. This in turn means that the delay in the system is not accurately known and this extra unknown delay has to be added to the dead time of the switching transistors. Having a long dead time (the period when both the pull-up and pull-down transistors have to be off to ensure that they don't get turned on together, which would short out the DC bus and cause system failure) is not a problem for Si or SiC systems, because they have a parasitic body diode that clamps the flyback voltage generated by the inductive reactance of the load to either the positive or negative rails.

GaN transistors don't have this body diode. This is a major advantage in creating our high frequency converters as Si and SiC transistors must have a parasitic body diode by virtue of the physics of their construction. And these waste energy on every converter switching cycle and this is a key reason why it is not feasible to run these converters past 100 KHz as too much energy is wasted in the body diodes!

As GaN doesn't have the body diode, you can switch fast without the cost of wasted energy in the body diodes, but there is also no diode to clamp the flyback of the load, so this means you need a very short dead time (when both transistors are turned off and there are no body diodes, the voltage can massively over or undershoot). And, you can't have a very short dead time unless you have an isolated gate driver with a very short propagation delay, that allows the dead time to be kept to 1-2ns. With such a short dead time, the load flyback voltage is kept to manageable levels (maybe 50V max), but with existing drivers and the long dead time that these require you to use, you may have 200V of flyback above your DC bus, which is 540V for 380V 3 phase systems. This would expose the transistors to ~750V and would destroy them or significantly reduce MTBF unacceptably.

CORE APPLICATION AREAS FOR OUR TECHNOLOGY

High power integrated motors

Not only does QPT technology cut the power requirements of electrical motors, it also solves a major industry problem of the size of VFD with a VFD design that is around 20 times smaller than today’s VFDs.

Electric Vehicles

Electric Vehicles or EV are an ideal market for our technology especially as it enables energy re-capture via regenerative breaking.

Heating, ventilation and air-conditioning (HVAC)

Heating, Ventilation and Air Conditioning (HVAC), uses a huge number of electric motors that are being driven with sub-optimal efficiency.

Robotics, Servos, Welding & Industrial Automation

Productivity can be improved by using qModules to control servo motors because they settle faster so more moves per hour can be achieved.